- Home

- About Us

- Our Products

- Acid Proof Tiles

- Acid Proof Bricks

- Chemical Resistant Bitumor Primer

- Chemical Resistant Bitumor Mastic

- Furomor Furan Resin Mortar

- Phenomor Phenolic Resin Mortar

- Cashewmor C.N.S.L Resin Mortar

- Epoxy Mortar

- Polyester Mortar

- Vinyl Ester Resin Mortar

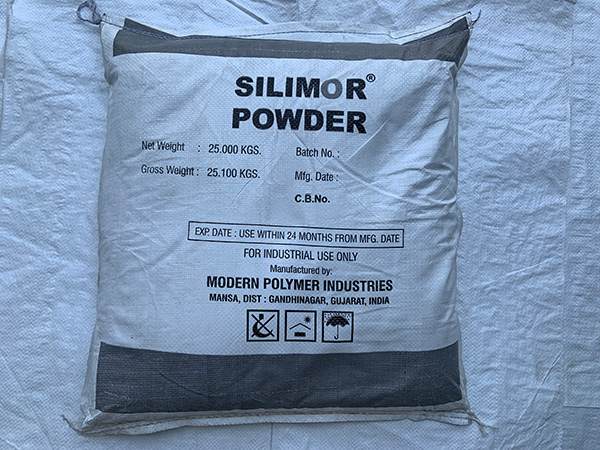

- Potassium Silimor Mortar

- Sodium Silimor Mortar

- Sulphomor Sulphur Mortar

- Epimor Coal Tar

- Carbon Tiles

- Services

- Export

- Technical Data

- Quality

- Gallery

- Clients

- Enquiry

- Contact Us